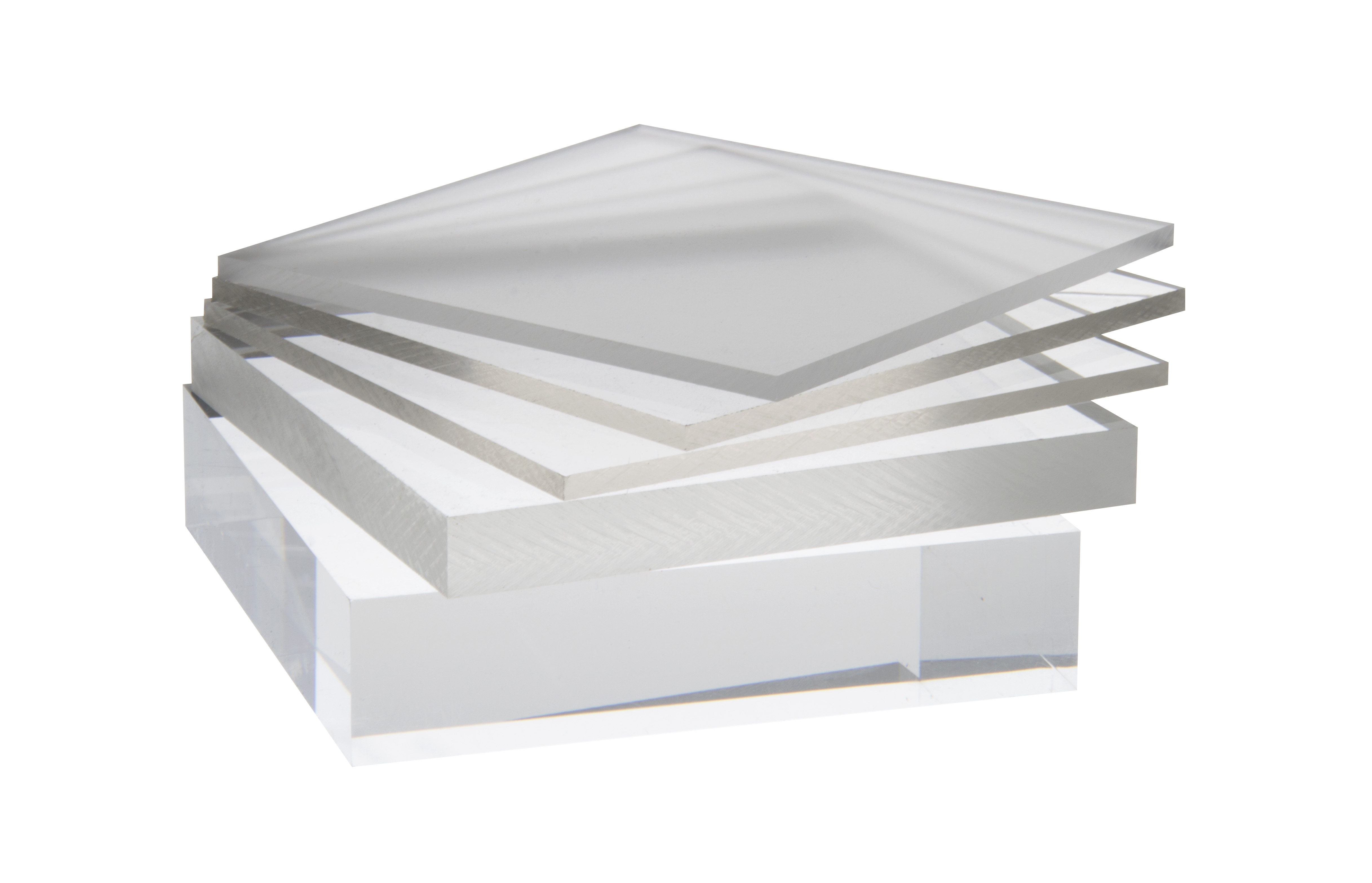

Methacrylate, PMMA).CELL CAST ACRYLIC PLEXIGLASS SHEET BLOCK CLEAR 5" x 3" 4" X OFFicial 3 Opaque sheet material made of acrylic glass (polymethyl PLEXIGLAS® proTerra is a double-sided coextruded, The 4 mm thick, solid-colored sheets are significantly impact-resistant and suitable for the easy installation in standard furniture profiles.

Additionally a hard coated, almost UV-resistant grade with excellent resistance to abrasion and chemicals is available. PLEXIGLAS® sheets with optical functionalities, high light guidance and distribution provide a uniformly bright and perfectly sharp picture, especially in display applications and for rear projection. These heat-reflecting PLEXIGLAS® solid and multi-skin sheets offer greater energy efficiency by cutting air conditioning costs.Īttractively mirror-coated and reflective solid sheets with a metallic, glossy or rainbow-colored surface. Solid sheets with a variety of classical and modern surface textures. Extruded PLEXIGLAS® XT is available in many different colours. The sheets have unrivalled resistance to ageing and weathering, are highly transparent, bright, break-proof and shock-resistant as well as being easy to shape and process. The twin-walled PLEXIGLAS® Alltop SDP 16 is a transparent, heat-insulating and highly weather-resistant sheet made from acrylic glass (polymethylmethacrylate/PMMA) which promises the clearest possible view and lowest possible construction effort.Įxtruded acrylic sheets (XT) have optimal thickness tolerances and high visual quality. These impact-modified molding compounds, multi-skin, corrugated and solid sheets and tubes combine toughness with excellent weather resistance. Specialty molding compounds provide injection-molded components with a high-gloss Class A surface and remarkable depth of color. PLEXIGLAS® molding compounds are characterized by a number of chemical, physical and technical properties which are indispensable for manufacturing high-quality components by injection molding, injection blow molding and extrusion processes.Ī noble appearance and special deep-view effect are the characteristics ofthese high-gloss solid sheets, which are available in various colors.

FLEXIGLASS SHEET ISO

PMMA molding compounds are standardized to DIN 7745 / ISO 8257. PLEXIGLAS® molding compounds are thermoplastics based on polymethyl methacrylate (PMMA). The sheets provide discreet light diffusion and come with one or both sides in various colours.Įlectrostatic dissipative ESD-glazings out of polycarbonate dissipate electric charges in a controlled way against earth. PLEXIGLAS® Satinice is pleasant to touch thanks to its velvety and warm surface. Specialty products for edge lighting and backlighting offer maximum light transmission without disturbing hot spots, as well as attractive color play effects. The new dimension of light: specialty PLEXIGLAS® sheets for efficient lighting applications combined with LEDs. They have an unsurpassed resistance to aging and weathering, and are highly transparent and brillant.Nevertheless they are easy to machine and break-resistant. There are two options for PLEXIGLAS® to bond: (1) ACRIFIX® 1S 0116 cement (viscous) for T- and narrow glue areas and (2) ACRIFIX® 1R 0192 1-Component-Reaction Bonding for colorless PLEXIGLAS®, light-curingīlocks in cast (GS) Acrylic glass are available in many thicknesses.

0 kommentar(er)

0 kommentar(er)